1.2344 Acier à outils pour travail à chaud

L'acier 1.2344 convient au traitement à chaud, aux matrices de moulage sous pression et d'extrusion, aux outils résistants à l'usure, aux outils de moulage sous pression, aux outils de pressage de métaux légers et de métaux lourds.

- fucheng steel

- Chine

- 1 mois

- 2000 tonnes/mois

- information

- vidéo

1.2344 TOOL STEEL

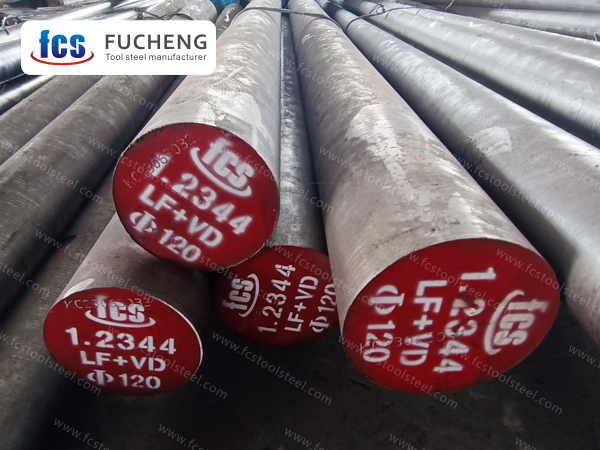

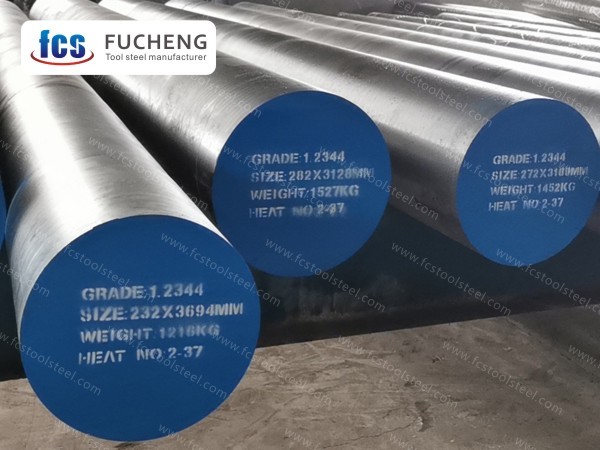

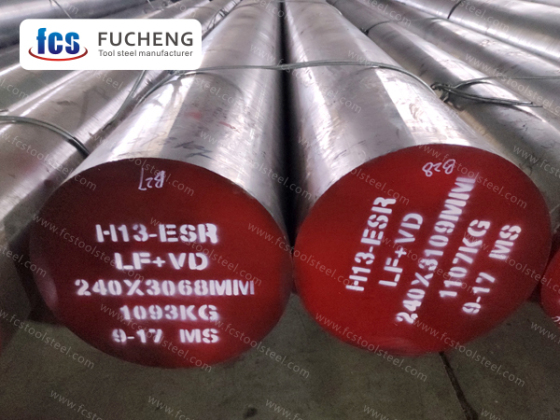

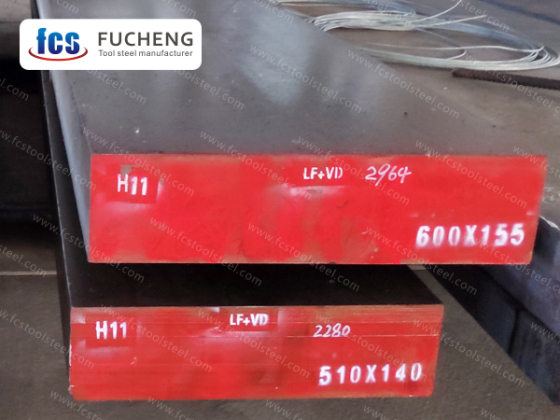

| Smelting and Manufacture Method: | LF+VD+ESR+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤235 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

1.2344 STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| DIN/W-Nr. | X40CrMoV5-1/1.2344 | 0.35~0.42 | 0.90~1.20 | 0.30~0.50 | 4.80~5.50 | 1.20~1.50 | 0.90~1.15 |

| ASTM | H13 | 0.32~0.45 | 0.80~1.20 | 0.20~0.50 | 4.75~5.50 | 1.10~1.75 | 0.80~1.20 |

| JIS | SKD61 | 0.35~0.42 | 0.80~1.20 | 0.25~0.50 | 4.80~5.50 | 1.00~1.50 | 0.80~1.15 |

APPLICATION

1.2344 steel is suitable for hot die processing, die casting and extrusion dies, wear-resistant tools, die-casting tools, light metal and heavy metal pressing tools.

1.2344 Heat treatment of mold steel

Forging, annealing, quenching, tempering

1050-850 ℃ 820-840 ℃ 1020-1050 ℃ 520-700 ℃

Purity: According to ASTME45 method A, A sulfide ≤ 0.5, B oxide, C silicate, and D spherical oxide ≤ 1 each, or DIN50602-K1 ≤ 10, or according to customer requirements.

Isothermal annealing specification

Annealing temperature (85010) C, insulation for 2 hours, cooling to (72010) ℃ with furnace, insulation for 4 hours, furnace cooling to below 500C, air cooling after discharge, hardness ≤ 229HBW.

High temperature tempering specification

Tempering temperature (73010) C, insulation for 2 hours, furnace cooling ≤ 500C, outlet air cooling.

Quenching and tempering specifications

Quenching temperature 850~880 ℃, oil cooled, hardness 50~52HRC; Tempering temperature 580-640C, outlet air cooling, hardness 28-36HRC

Specification for pre hardening treatment

Heating temperature 860-900C, oil cooled, tempering temperature 570-70OC, air cooled, tempering hardness 28-35HRC.

1.2344 Physical properties of mold steel

(1) Density: 7.31g/cm.

(2) Linear expansion coefficient:

Temperature 18-100 ℃ 18-200C 18-300C 18-400C 18-500 ℃ 18-600 ℃ 18-600 ℃

Linear expansion coefficient 11.910K 12.2010K 12.5010K 12.8110K 13.1110K 13.4110K 13.7110K

(3) Elastic modulus: (20C) 212000MPa, shear modulus (room temperature) 825000MPa, Poisson's ratio 0.288

(4) Thermal conductivity:

Temperature 20 ℃ 100 ℃ 200C 300C 400C

Thermal conductivity 36.0 [W/(mK)] 33.4 [W/(mK)] 31.4 [W/(mK)] 30.1 [W/(mK)] 29.3 [W/(mK)]

Application status: 30-56HRC.

Pre hard hardness ≤ 28HRC; Annealed state, hardness ≤ 22HRC