Acier à outils pour travail à chaud HD

L'acier HD est une sorte d'acier à matrice de travail à chaud durcissant par refroidissement par air et à haute ténacité. L'acier HD a une bonne résistance et ténacité à haute température, une dureté à haute température, une stabilité thermique et une résistance à la fatigue thermique.

L'acier HD est souvent utilisé pour le poinçon d'extrusion à chaud de tuyaux médicaux en acier, la matrice inférieure d'extrusion et l'aiguille de perforation de tuyaux en alliage de cuivre, le poinçon de roulement d'extrusion à chaud et la matrice concave, la matrice basse d'extrusion de valve, etc. La durée de vie est plus longue que celle de l'acier H21.

- fucheng steel

- Chine

- 1 mois

- 2000 tonnes/mois

- information

- vidéo

HD HOT WORK TOOL STEEL

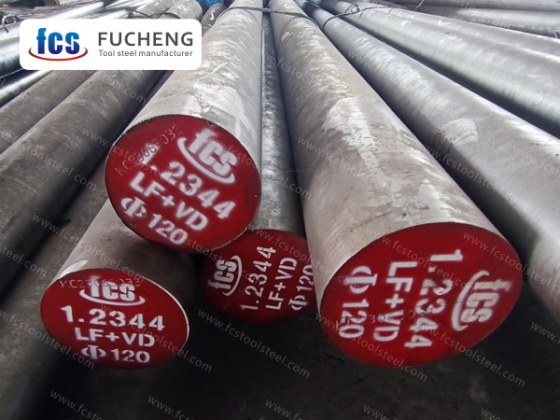

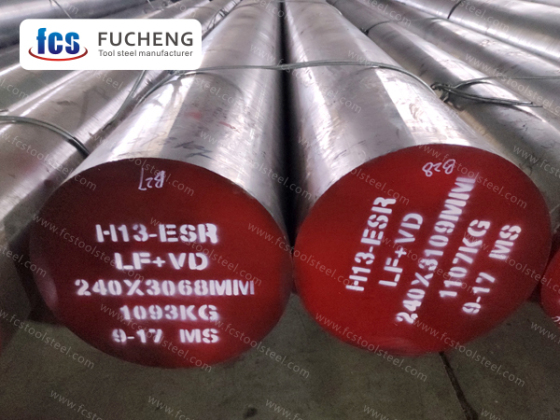

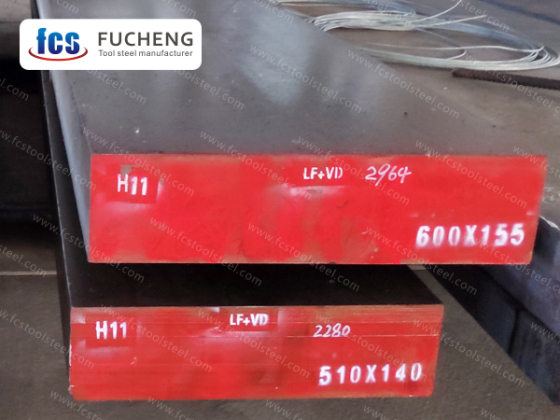

| Smelting and Manufacture Method: | LF+VD+Forged |

| Delivery Condition: | Annealed |

| Delivery hardness: | ≤220 HBS |

| UT Test Standard: | Sep 1921-84 Class3 D/d,E/e |

HD STEEL GRADE COMPARISON AND CHEMICAL COMPOSITION COMPARISON

| Standard/Steel Grade | Chemical Composition(%) | ||||||||

| C | Si | Mn | Cr | Mo | V | Ni | Nb | ||

| GB | HD/4Cr3Mo2NiVNb | 0.35~0.45 | ≤0.35 | ≤0.40 | 2.50~3.00 | 1.80~2.20 | 1.00~1.40 | 0.80~1.20 | 0.10~0.25 |

APPLICATION

HD steel is often used for hot extrusion punch of steel medicine pipe, extrusion bottom die and perforation needle of copper alloy pipe, hot extrusion bearing punch and concave die, valve extrusion low die and so on.

HD steel characteristics

HD steel, also known as 4Cr3Mo2VNiNb, is a high toughness hot work mold steel, also known as air cooled hardened steel. This is a steel grade developed by China on the basis of UHBQR080 steel. Unlike many traditional hot work mold steels, HD mold steel does not contain cobalt elements, but adds 1% nickel and trace amounts of niobium, boron and other elements, making it excellent in terms of strength, toughness, hardness, thermal stability, and thermal fatigue resistance at high temperatures.

In addition, HD steel has a high fracture toughness, which is 50% higher than 1.2581 steel at the same hardness; At a high temperature of 700 ℃, its tensile strength can be increased by 70%, while its cold and hot fatigue resistance and thermal wear performance can be doubled and 50%, respectively. The standard quenching temperature for ordinary quenching and tempering of HD mold steel is 1130 ℃± 10 ℃, and it is quenched by oil or gas cooling; Tempering temperature 590 ℃± 10 ℃.

Due to these excellent performance characteristics, HD mold steel is widely used in the manufacturing of various types of molds. For example, the working conditions for hot extrusion of large caliber projectile blanks are high temperature, high pressure, and alternating cold and hot. As a hot extrusion punch, the material requirements are very strict, so HD mold steel can be used to replace the traditional hot work mold steel 1.2581 that has been used for a long time.